The Design of Steel Structure Workshop

2021-07-26

The attention in the design of steel structure workshop:

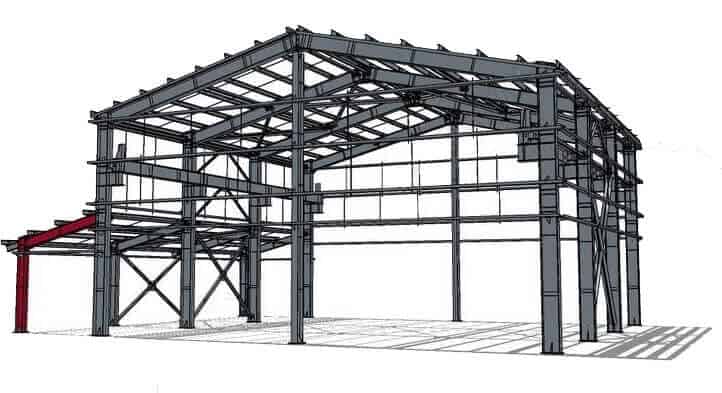

Load-bearing of steel workshop building

The first thing that needs to solve in the design of steel structure factory building is the load-bearing. The steel structure workshop building has to withstand construction loads, rain, dust, wind load, snow load, and maintenance loads.

The load-bearing performance of the metal roof panel is related to the section characteristics of the corrugated metal sheet type, strength, thickness, the force transmission method. And the spacing of the purlins. So the load-bearing problem needs to pay attention to when designing the workshop building.

The structural form of the steel structure workshop:

The roof panel could adopt corrugated metal cladding and cold-formed steel purlins.

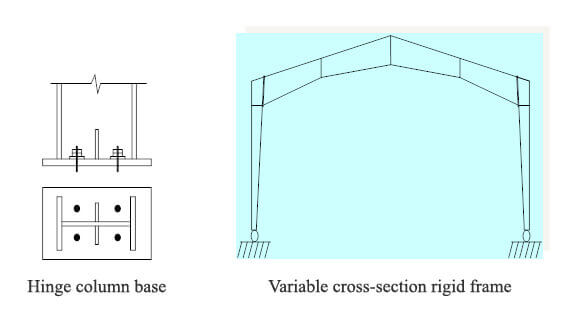

For workshops without cranes, the main rigid frame can use a variable cross-section rigid frame. Both beams and columns are variable cross-sections, and the column base is a hinge connection, which is economical and safe.

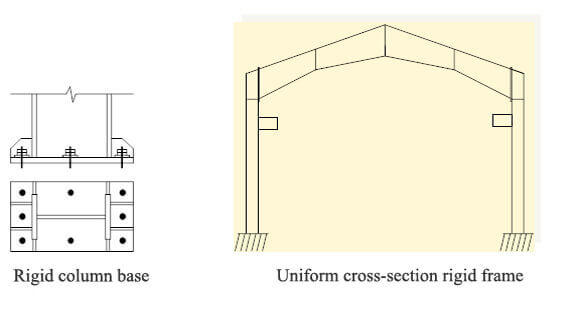

For workshops with cranes, the columns should not be of variable cross-section, but uniform cross-section. Still, steel beams can be of variable cross-section, and the column base is a rigid connection, which is safe and economical.

The Lighting for the design of steel structure workshop

The area of steel structure workshops is vast, and lighting is also a big problem. Especially in some industrial workshops, light is an essential facility. Improve indoor lighting through daylighting panels during the day to save energy.

When arranging daylighting panels or glass at specific locations of the metal roof. The service life of the skylight should same as the metal roof panel. The waterproof treatment should apply at the junction of the daylighting panel and the metal roof sheet.

Moisture-proof

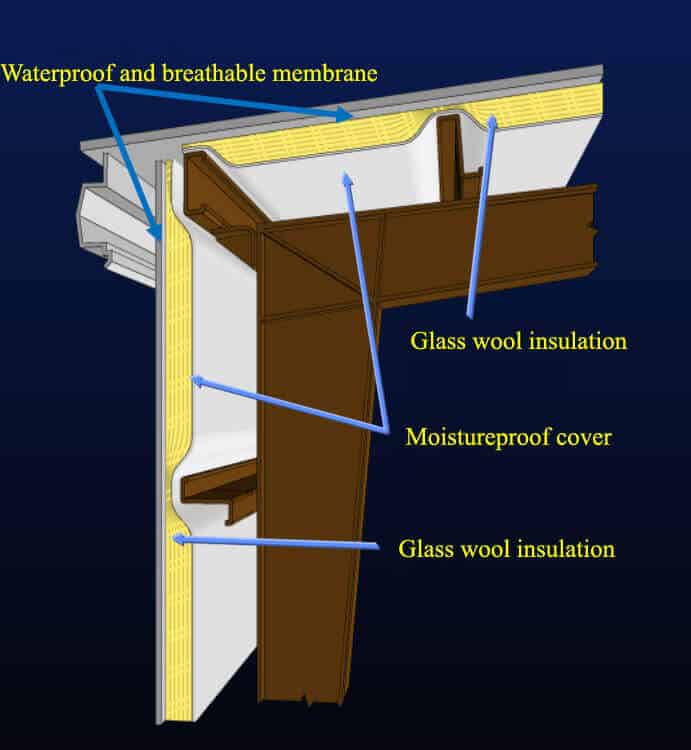

Summer is a rainy season. To prevent water vapor from the bottom of the metal roof, it needs to remove the water vapor in the metal roof.

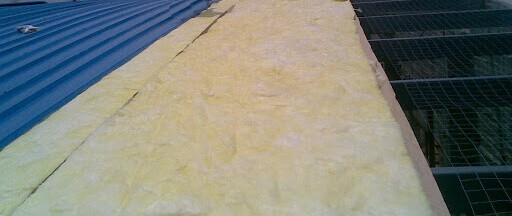

The metal roof layer should fill with insulation cotton, and the metal roof bottom sheet lay with a waterproof film. And there are ventilable on the metal roof, which will be moisture-proof for steel structure workshop.

Fireproof for the design of steel structure workshop

The design of steel structure workshop needs to consider the design of fireproof. During the use of a steel structure workshop, there is a significant hidden danger if meet fire disaster.

When the components of the steel structure workshop exceed a specific temperature, the strength and yield strength of the parts will decrease, which is easy to cause collapse accidents.

Therefore, the steel structure workshop needs to spray with fireproof materials, which can improve the fire resistance of the construction in the event of a fire.

Sound insulation

During the production and construction process, it is inevitable that noise will generate. The steel structure factory building prevents sound from being transmitted between indoors and outdoors.

Fill the metal roof layer with sound insulation material (usually made of insulation cotton), and the sound insulation effect expressed by the difference in sound intensity on both sides of the metal roof.

The sound insulation effect is related to the density and thickness of the sound insulation material. It should note that sound insulation materials have different blocking effects on the sounds of different frequencies.

Thermal Insulation

Steel structure workshops should also pay attention to the issue of thermal insulation. If the steel structure workshops built in the cold region, which must consider the heat preservation in winter.

The thermal insulation function realized by filling thermal insulation materials (commonly used glass wool and rock wool) under the metal roof panel.

The thermal insulation performance determined by the following factors: the raw material, density, and thickness of the thermal insulation cotton. The humidity of the thermal insulation cotton, the connection method of the metal roof panel, and the underlying structure(to prevent the “cold bridge” phenomenon). The repeated the ability of the metal roof layer to heat radiation.